Everything you see - Made by Me

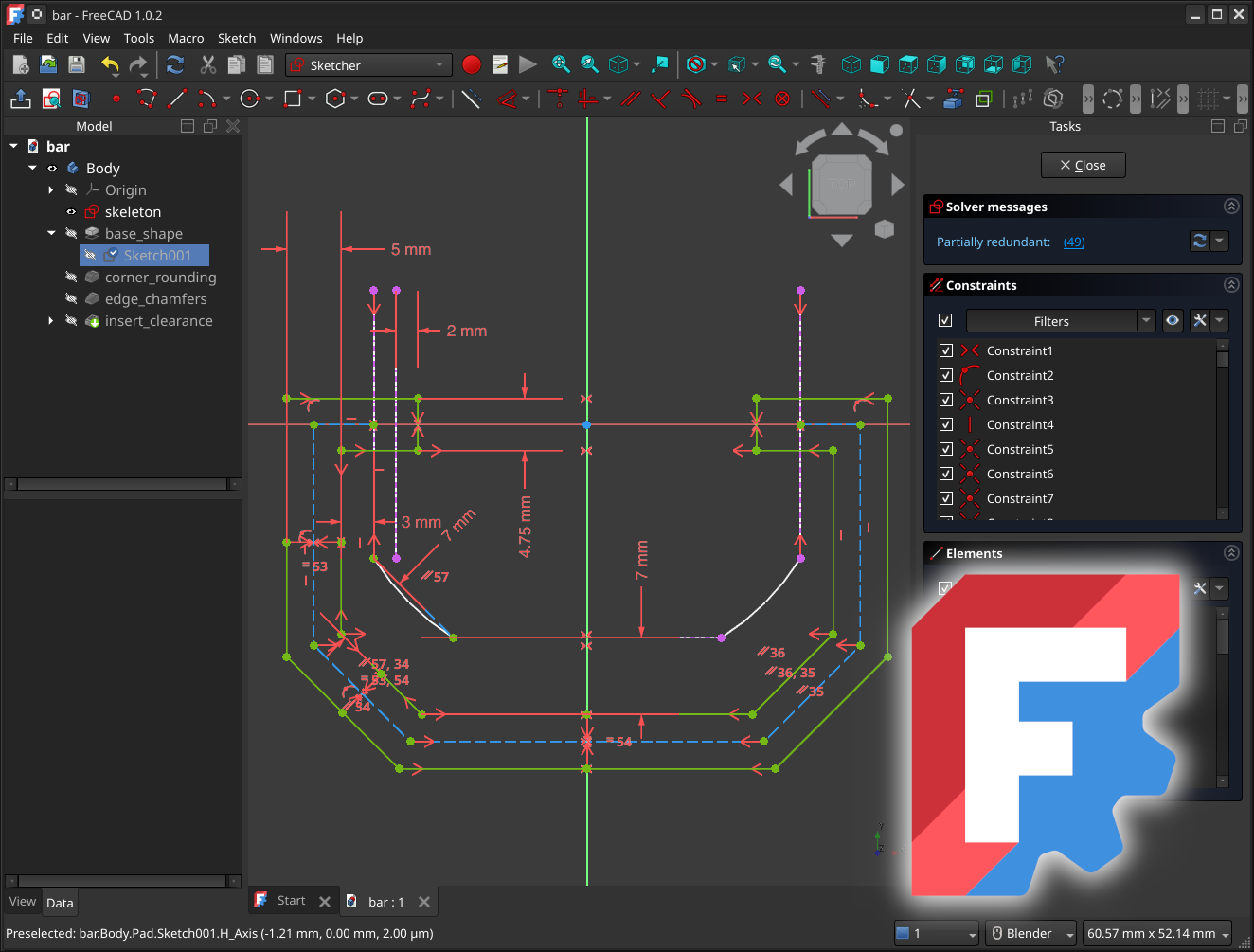

All my modeling work is done using FreeCAD, giving me the flexibility and freedom to have full ownership of my creations! I often start my designs on a piece of paper, sketching out a rough idea before I move on to realizing the idea in FreeCAD. On occasion, I also make use of synthetic modeling clay to wrap my head around how the end product will look before committing to a particular design..

All of the work I do is on a Prusa XL 2-tool 3D printer. Having multiple print heads grants me the flexibility to print objects using multiple materials embedded together, and the volume to print extremely large objects with ease. In addition to printing with multiple toolheads at once, I also make use of high-durability hardened nozzles to allow printing of abrasive materials such as wood, carbon-fiber, and glass filled plastics.

All my prints are hand-processed with simple tools like razors, sandpaper, and glue. I intentionally design my products such to avoid as much hand-processing as possible, which helps to reduce issues with any assembly as well as improving consistency. Reducing waste is also an important result of minimizing post-processing, a core pillar of 5S lean manufacturing principle.